People are constantly looking for cheaper and more efficient ways to do their jobs, and this is especially true in the manufacturing industry. If you’re wondering what the internet of things has to offer for manufacturing companies, take a look at these 5 examples of how some have been using it so far.

A Primer on Internet of Things

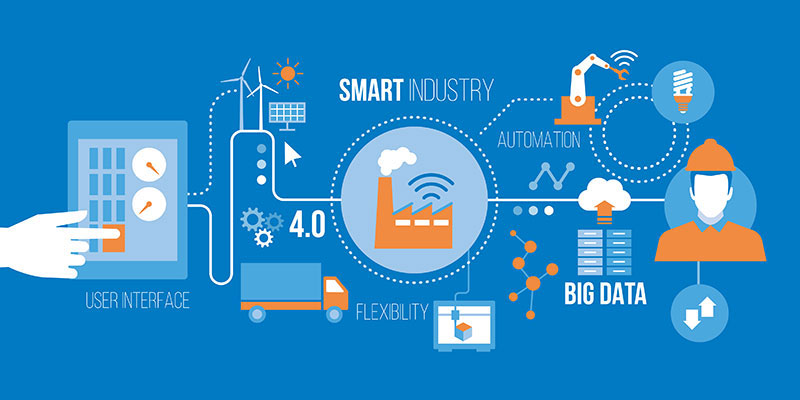

The Internet of Things, commonly abbreviated as IoT, is a system of interrelated computing devices, mechanical and digital machines, objects, animals or people that are provided with unique identifiers (UIDs) and the ability to transfer data over a network without requiring human-to-human or human-to-computer interaction.

Just like users lately realised the importance of videos in social media marketing strategy. IoT has been heralded as a game changer for manufacturing. By networking together physical objects and systems, manufacturers can collect data about every aspect of their production process and use it to make real-time adjustments that improve efficiency, quality and safety.

Some of the ways that IoT is being used in manufacturing today are given below:

- Tracking inventory levels and automatically reordering when stocks run low;

- Monitoring equipment for signs of wear and tear and schedule maintenance before problems arise

- Analysing data from production runs to identify trends and optimize processes;

- Using sensors to detect potential hazards and prevent accidents;

- Connecting workers with critical information via wearable devices;

- Collecting data about customer usage patterns to inform new product development;

- Reducing energy consumption by automatically controlling lights, temperature and other environmental factors;

- Simplifying compliance with regulatory requirements by providing real-time visibility into all aspects of production;

- Enhancing security by tracking the location of people, equipment and assets;

- Enabling predictive maintenance that can minimize disruptions and downtime

Uses of IoT in the Manufacturing Industry

The use of the Internet of Things in manufacturing is becoming more prevalent as the technology becomes more affordable and easier to implement. Here are some ways that manufacturers are using IoT to improve their operations:

1. Tracking production data in real-time

By attaching sensors to equipment and products, manufacturers can track production data in real-time. This allows them to identify issues early on and make necessary adjustments to improve efficiency.

2. Automating repetitive tasks

By connecting devices and machines to each other, manufacturers can automate repetitive tasks. This frees up workers for other tasks and reduces the chance of human error.

3. Enhancing safety

Sensors can be used to monitor conditions in the workplace and identify potential hazards. This helps to keep workers safe and enhances the overall safety of the facility.

4. Reducing downtime

Downtime is a major issue for manufacturers, as it can lead to lost production time and revenue. By using IoT, manufacturers can monitor their equipment for signs of failure and take preventive measures to avoid costly downtime.

5. Improving quality control

Quality control is essential for any manufacturer, but it can be a challenge to track all aspects of production manually. Sensors can be used to automatically collect data about the manufacturing process, which can then be analysed to identify areas for improvement.

Data Overload: More Is Not Always Better

Data overload is a common problem in manufacturing. Too much data can lead to analysis paralysis, where decision-makers are overwhelmed by information and unable to make informed decisions.

The Internet of Things can help alleviate some of the pressure of data overload by providing real-time data that is relevant and actionable. For example, sensors can be used to monitor machinery for signs of failure or downtime. This data can then be used to improve preventive maintenance schedules and avoid costly downtime.

Additionally, the use of big data analytics can help sift through large amounts of data to identify trends and patterns. This can help manufacturers make better decisions about production planning and inventory management.

Ultimately, the goal is to use the Internet of Things to reduce costs and improve efficiency in manufacturing. By leveraging the power of real-time data, manufacturers can stay ahead of the competition and keep their operations running smoothly.

Privacy Concerns and the IoT

The internet of things is becoming increasingly prevalent in manufacturing as more and more devices are connected to the internet. However, there are privacy concerns associated with the IoT that need to be considered.

When it comes to IoT, manufacturers need to collect data from various devices to improve their operations. This data can include everything from production data to employee data. However, this data can also be used to track employees and customers, which raises privacy concerns.

There are a few ways that manufacturers can address these privacy concerns:

1. Collect only the necessary data

There is no need to collect more data than is necessary for improving operations. Manufacturers should only collect the data that they will use.

2. Use anonymized data

Whenever possible, manufacturers should use anonymized data instead of personally identifiable information (PII). This will help to protect the privacy of employees and customers.

3. Keep data secure

Data security is critical when it comes to the IoT. Manufacturers should ensure that all data collected is stored securely and that only authorized personnel have access to it.

4. Be transparent

Manufacturers should be transparent about what data they are collecting and how they are using it. Employees and customers should be made aware of how their data is being used and should be allowed to opt-out if they do not wish for their data to be collected or used in certain ways.

Conclusion

The Internet of Things is having a profound impact on manufacturing, with factories all over the world using IoT-enabled devices and systems to improve efficiency, quality control, and safety. In this article, we’ve looked at five ways that the Internet of Things is being used in manufacturing today. As you can see, the applications of IoT in this sector are vast and varied, and it’s only going to become more commonplace in the years to come. If you’re involved in manufacturing in any way, it’s well worth keeping up with the latest developments in this area.

2 thoughts on “5 Ways IoT is Being Used in Manufacturing Today”